4JET's PEARLs

Laser Filamentation for many Application Areas

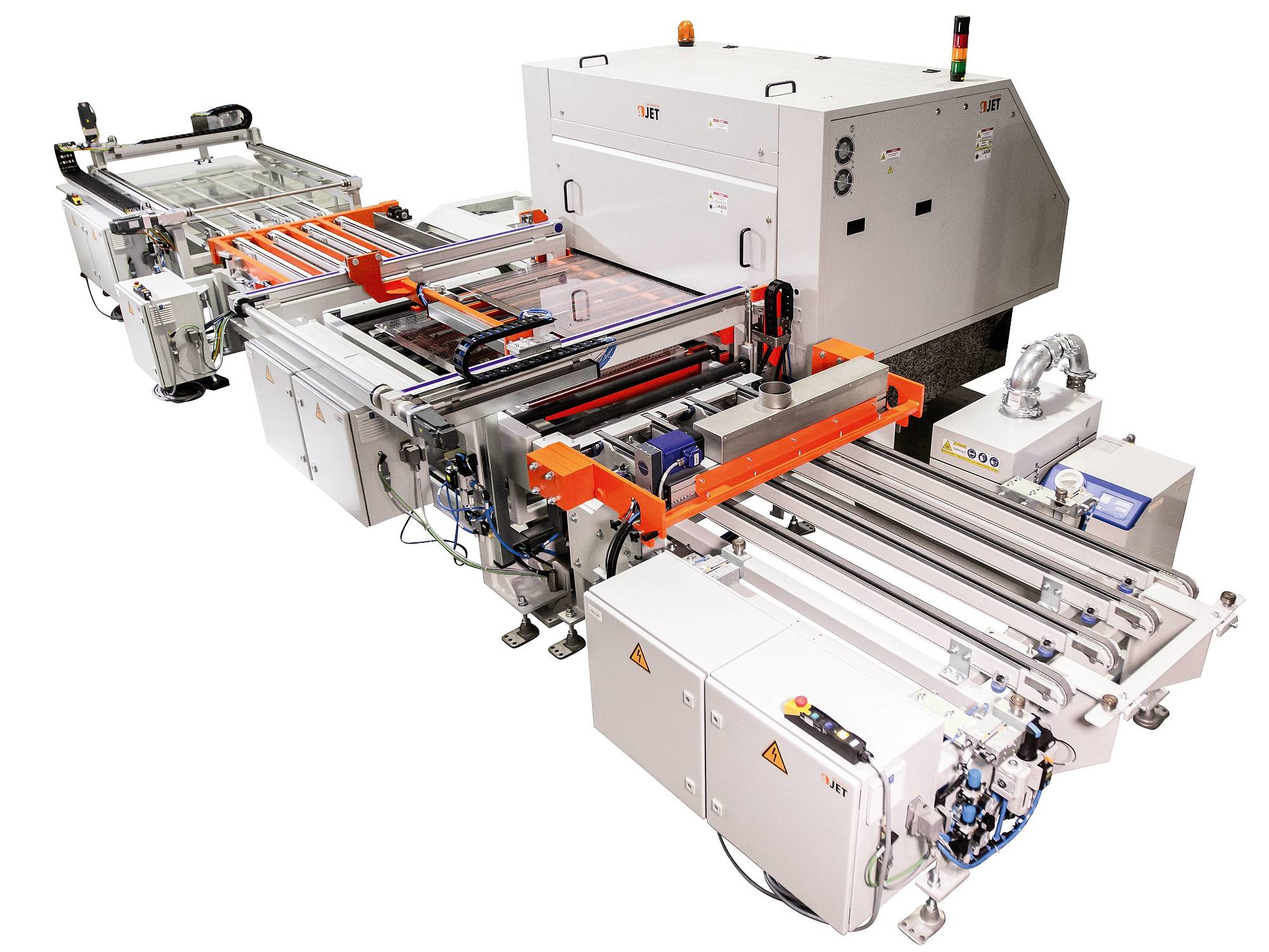

We call the laser-based glass filamentation PearlCut, because the filaments in the glass look like pearls strung on a string. What could be more obvious than to call our laser systems PEARLs. Our PEARLs combine filament based glass cutting and CO2 laser cutting in one processing head. Filaments are used to weaken the glass, which is then separated by heating, expansion and the generation of tensile stress. Where cycle times require it, the two processes can be divided into 2 PEARLs arranged one behind the other. It is also conceivable to subsequently apply a mechanical breaking process to a PEARL filament process.

Our PEARLs can be used for glass cutting in a wide range of applications and industries, e.g.:

- cover glasses for a wide range of electronic applications

- cutting transportation glass for trains or cars, i.e. interior or exterior glass (mirrors, side windows, windscreens, etc.)

- specific architectural glass like smart windows

- or technical glass for e.g. optical substrates

Scalable in size and with options according to your requirements

The PEARLs are based on granite, which offers inherent accuracy and long-term stability. The coefficient of thermal expansion of granite is 4 times lower than that of steel. This guarantees a sustainable production of high precision and high quality products. The specific tuning of the axis controllers not only results in a high cutting speed, but also in excellent path accuracy to achieve high-precision outer contours in the end product. An optional autofocus offers further advantages with regard to the robustness of the process window without having to accept a loss of process speed.

Our PEARLS are currently available in three versions with three standard working ranges. The length of the L and XL systems is scalable. Other sizes on request!

- 1.5 m width and length 0.85 m as PEARL M

- 1.5 m wide and scalable in length as PEARL L

- 2.2 m wide and scalable in length as PEAR XL

PEARL M

The PEARL M substrate table has been developed as a reliable and cost-effective base for the precise cutting of small to medium-sized glass substrates into individual products. The PEARL M substrate table can be configured to process ultra-thin glass with a thickness of approximately 30 µm up to a glass thickness of 8 mm. Various laser and optical packages can be integrated to optimize performance depending on glass thickness and coating.

An optional carrier allows filamenting and separation in one machine, saving space and additional costs for a second machine. A full automation option including a glass carrier rotation and glass waste disposal is available to minimize operating costs.

| working area | 1.500 x 850 mm² |

| glass thickness | 30 µm up to 8 mm |

| single path cutting | up to approximately 3 mm with standard optics package |

| cutting speed | up to 1 m/s and above depending on glass |

| path accuracy | +/- 5 µm |

| footprint | 3.000 x 3.000 mm² (machine only) |

| footprint including access area | 6.500 x 4.000 mm² |

| weight | appr. 8t |

| loading and unloading | manual or automatic |

PEARL L

4JET's PEARL L is a 24/7 inline production machine for cutting single glasses or glass stacks along straight lines or in free contours. The PEARL L is based on the same gantry as the PEARL M, but offers an enlarged working area for larger glass substrates. The standard glass size is 1.5 x 3.0 m², the machine length can be scaled to even longer glasses. The substrate table of the L offers the P/V mode, P(ressure) to transport the glass, V(acuum) to fix the glass - this is cost effective, while providing excellent stability of the glass position in z.

The lightweight construction of the substrate table allows high acceleration values, even with heavier glasses, to achieve a short process time. The PEARL DYNAMIC FOCUS is an option to ensure that the focus is always within the process window without increasing the process time. Other interesting options are available, such as the CO2 separation described above.

| working area | 1.500 x 3.050 mm², scalable in length |

| glass thickness | 30 µm up to 8 mm |

| single path cutting | up to approximately 3 mm with standard optics package |

| cutting speed | up to 1 m/s and above depending on glass |

| path accuracy | +/- 5 µm |

| footprint | 6.716 x 2.500 x 1965 mm³ (machine only) |

| footprint including access area | 9.295 x 4.890 mm2 |

| weight | appr. 14,5t |

| loading and unloading | automatic |

| upstream and downstream comm. | Digital I/O, PN/PN coupler, Anybus-Coupler |

| MES | upon request |

PEARL XL

The characteristics of the PEARL XL are easy to it explain, it is an L for even larger glass substrates with a width of up to 2.2 m, equipped with the same features as the L.

You may ask yourself, what is the XXL? Talk to our experts about what is possible.

Contact

We look forward to your questions – our experts are at your disposal.