SCANNECT – 2D Code Marking

Scan & Connect your Tire

The 4JET SCANNECT solution – short for “scan & connect” - enables a long standing wish of the tire and automotive industry: being able to trace tires throughout their life cycle and to get in closer touch to the end customer. Unlike machine readable paper barcodes, which have a limited life span, moulded DOT codes, that are not unique, RFID tags, that are expensive and lack maturity, or engraved plain text serial codes, that require to type in numbers offline, the SCANNECT solution enables to individually laser mark every tire with a unique and permanent machine readable 2D matric code. SCANNECT Codes can be read with every smartphone, contain information required during tire processing or may be directly linked to a web based database with such information. 2020 SCANNECT 2D matrix codes account for more than 90% of all connected passenger car tires.

Robust Machine Reading Based on proven DMC and QR Code Technology

Based on existing most reliable 2D matrix code technology SCANNECT Codes enable enormous data capacity while providing data redundancy to prevent misinterpretation of data and data redundancy to recover data in case of code damage or contamination. Coding protocols are widely used industry standards and are supported by all professional 2D code reading devices. A patented surface structure captures light to generate “SCANNECT super black” in the dark portions of the 2D codes, providing sufficient contrast to enable high reading rates with automatic readers.

Laser engraving process

Marking is performed by 4JET´s proven line of T-Mark systems, which are widely used in tire manufacturing worldwide. The laser markings are applied to the cured tire, either at the tire plant or further downstream in the tire warehouse, where tire markings are applied according to customer demand.

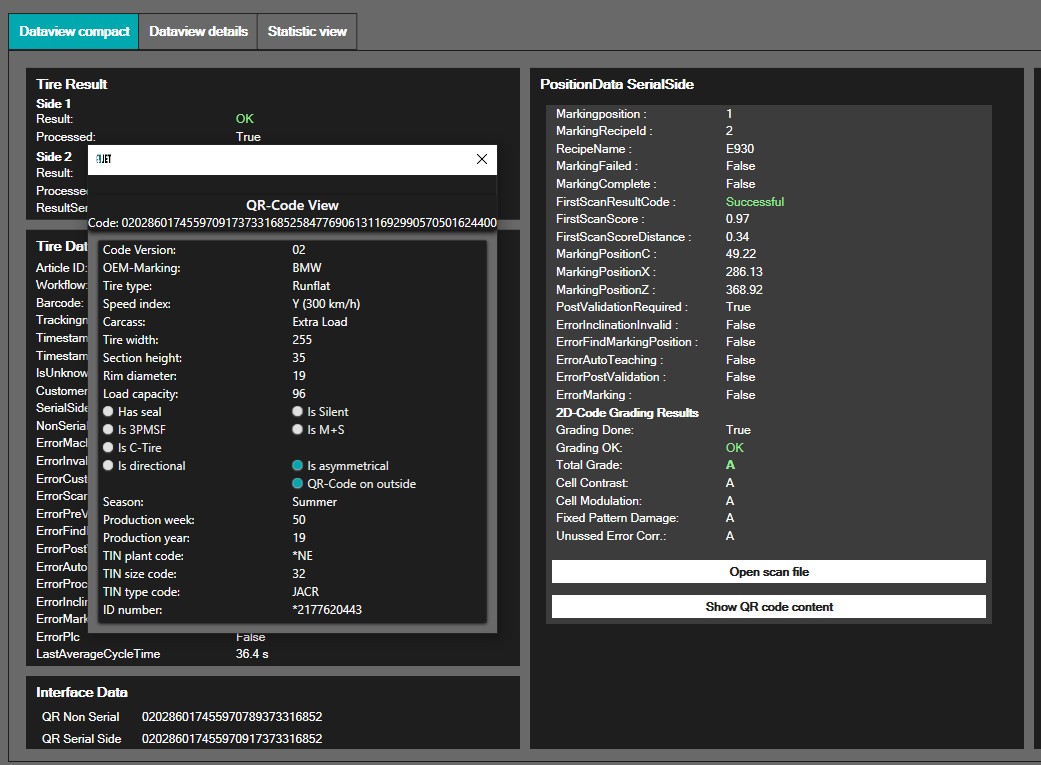

4JET’s T-Mark systems are able to read the DOT week code from the tire in order to ensure that information on the sidewall and code match. An auto-teach functionality allows new tires to be marked without prior teach-in process and the system can pick one of several possible marking locations depending on existing colour markings. SCANNECT Codes are auto-corrected to account for sidewall angles and curvature of the tire and within the T-Mark system SCANNECT 2D Matrix Codes can be validated or graded according to ISO/IEC 29158 to account for the high quality standards of the automotive industry

The SCANNECT marking can be combined with a human readable serial number. Furthermore, logos as well as other customer or country specific engravings can be added during this production step, allowing for increased production batches and/or reduction of stock levels.

Full solution Provided

Together with the tire marking equipment 4JET offers a comprehensive solution packet around the SCANNECT technology. The automated T-Mark laser marking system is complemented by the T-Mark compact handheld laser engraving, the SCANNECT reading bridge, the SCANNECT patch engraver and the mobile SCANNECT grading station.

Contact

We look forward to your questions – our experts are at your disposal.