T-Mark

Fully Automated Laser Tire Marking System

Industry Standard

With hundreds of installations worldwide the T-Mark fully automated tire laser marking system and T-Mark Compact – 4JET’s mobile laser marking system – can be found at production sites in Europe, Americas and Asia at all major tire makers. The highly flexible system is capable of marking bitmaps, DXF graphics, numbers and characters as well as 2D matrix codes on the sidewall of any tire within the range from typical 14 inch tires up to 25 inch super-single truck tires in random order. The short cycle times, the robustness, the broad range of applications and the built-in quality control features as well as the intuitive user and maintenance concepts truly make the T-Mark the industry standard for this application.

Key Performance Indicators are Leading Edge

The cycle time depends on the size of the engraving and the quality procedures selected. In the standard configuration our high volume systems can process over 1 Mio. tire markings per year.

Properly maintained and under the recommended 4JET’s maintenance contract the machines have a typical uptime of > 95%, a very low energy consumption and do not need consumables except aspiration filters and cleaning detergents. The contact-free laser process not only provides perfect tire surfaces but also keeps the wear part cost down.

The system runs fully automated and if equipped with the auto-teach feature, there is also no staff required for the teach-in of new tire models. Daily operation does not require engineer’s skill and only very limited training. The T-Mark only requires a footprint of 2 x 2 m for the core system. The total footprint including e-cabinet, aspiration unit, conveyor connection and access routes depends on the individual setup and usually amounts to around 16 m².

Laser Marking is Robust, Flexible and Safe

After automated feed-in and handover of tire and processing parameters to the system, the tire is positioned underneath the processing head which is installed on a pivot axis in line with the tire axis of rotation. Based on a 3D scan, the tire sidewall is read and the marking area is identified according to a defined position with regard to a specified reference mark on the tire sidewall.

Based on a user-defined recipe per tire type, required pre-validation steps, one or more marking procedures, post-validation steps and/or tire flipping steps are automatically executed. Pre-validation and post-validation data is logged and transferred to the customers’ MES after feed-out of the tire.

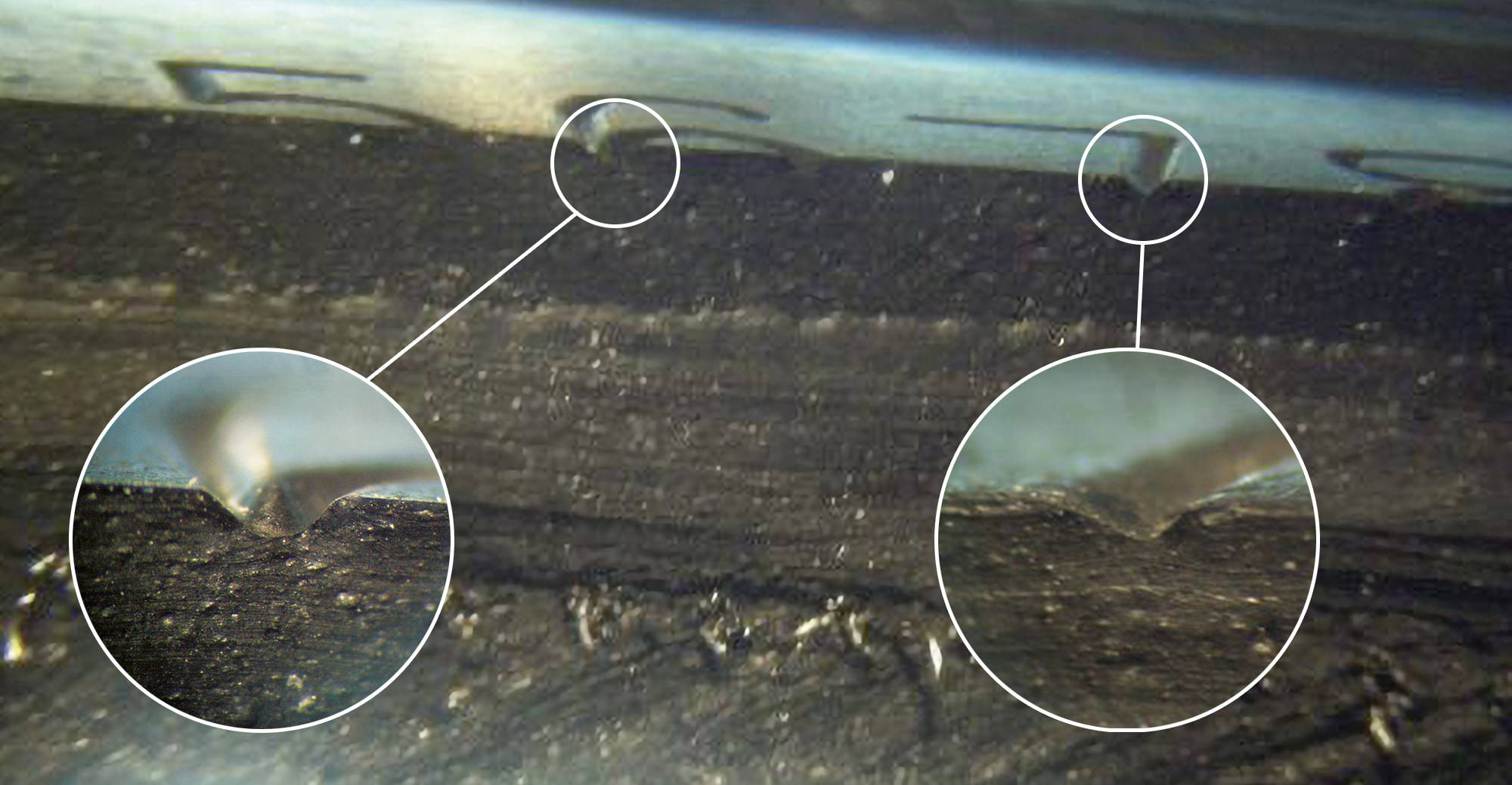

The core laser process itself is based on a low-hazard CO2 laser, which can easily be contained in the system by the transparent housing of the T-Mark, providing a safe laser class 1 solution. The desired removal of the sidewall rubber is based on so called laser ablation, a process that transfers the sidewall material into a mixture of gas and carbon being extracted into the filter of the aspiration unit. The process energy is contained locally at the marking spot, providing high energy efficiency and preventing the deeper layers of the tire sidewall from getting damaged. At the same time, the Gaussian shaped laser beam provides smooth and rounded traces on the sidewall, notch effects are prevented.

Important features

4JET’s market leading tire marking technology comes with a comprehensive set of build in or optional features, ensuring top quality, high efficiency and extremely reliable production. A state of the art sensor suite monitors the processes and detects process deviations such wrong tire feed-in or tire deformation.

An easy to operate workflow system allows the intuitive generation of new tire recipes and workflows provide the flexibility to use the system for different applications, depending on the tire type or specific requests from the customer’s MES.

Several potential marking locations can be compared prior to marking in order to prevent existent match dots or balance marks from being destroyed by the engraving. Markings can be validated using optical matching in comparison to a reference engraving, optical character recognition or depth validation. The shape of marking (e.g. QR codes) can be compensated to account for sidewall curvature or sidewall angle (projection correction).

Areas of Application

Being able to mark all sorts of logos, characters, numbers or 2D matrix codes opens a broad range of applications for the T-Mark system. Tires can be traced individually and machine readable markings can be used to connect the tire to the car it is fitted on. Marking of logos or legally required insignias allows for the reduction of inventory and helps to reduce the complexity in tire production.

4JET T-Mark Technology International Property Rights

As the market leader for laser-based machine tools, we regularly spend a double-digit percentage of our turnover on further development. To protect these investments, we maintain a portfolio of international industrial property rights for our systems, processes used and/or products manufactured with our processes. The most important of these intellectual property rights are listed below:

EP2905125, EP2977934, EP3147114, EP3238928, US2006/0161381, EP32818101, DE202014010855, DE202014011007, DE202017103420, US2018/00456111, EP3284586, CN107743450, KR10-2017-70367681, EP32978161, DE2905125, FR2905125, GB2905125, CA29993751, EP34486681, CA30223411, DE602014036348, CN1100146801, DE3147114, FR3147114, GB3147114, DE 20 2020 104 479.6, WO 2018/224601 (DE)1, WO 2018/224601 (KR)1, US 2019/0135011

1 property right pending (status August 2020)

Contact

We look forward to your questions – our experts are at your disposal.