Functional Surfaces

4JET’s economical solution for laser based large area surface pattering

Today, laser processes are used in countless industrial applications for cutting, welding, ablation, polishing, annealing, pretreatment and in general for modifying materials in one way or another. Nearly all of these processes are based on a relatively simple laser beam that is strongly focused on the material to trigger one of the above mentioned effects within a tiny volume. This laser spot is then moved very quickly over the surface using high-speed deflection systems to cover the area to be treated or to create the desired pattern. For larger areas, this is like using a tiny brush to sweep a town hall square - it takes forever.

LALIP – Large Area Laser Interference Patterning

Let’s think differently. In many of those applications the laser needs to create some kind of repeating, periodic pattern on the surface. Exactly for those applications, 4JET has developed a completely new and innovative technology to create such periodic patterns in a faster, more accurate and more reliable way compared to traditional laser processing. We call it LALIP – Large Area Laser Interference Patterning.

Interaction between laser beams

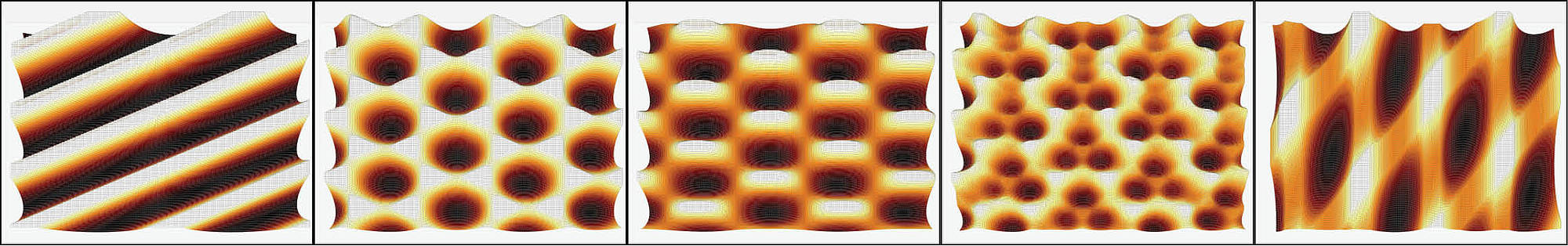

The magic word in this context is "interference". Think back to your physics lessons at school: One of the many fascinating properties of laser beams is their coherence, i.e. all wave trains of a laser beam have a fixed phase relationship with each other. This means that whenever two or more laser beams cross and overlap, they interact or interfere with each other in a temporally and spatially stable manner. In some areas of their interference they jointly produce very bright light (additive superposition), in other areas they even cancel each other out (subtractive superposition) and leave areas completely dark: The laser beams interfere and produce an alternating, periodic pattern of light. The magic word in this context is “interference”. Think back to your physics class in school, laser beams were described with their fascinating property called coherence which allows them to do fancy things. Laser beams usually exhibit an extremely long, so-called coherence length. As a consequence, whenever two or more laser beams cross and overlap, they interact with each other in a stable manner – in terms of time and space. In some areas of their interference they join forces to produce very bright light while in other areas they actually cancel each other out and leave areas completely dark: The laser beams interfere and create an alternating, periodic pattern of light.

High-speed processing speed thanks to LALIP

With Large Area Laser Interference Patterning (LALIP), 4JET actually uses exactly that periodic pattern of light to cut, weld, ablate, polish, anneal, pre-treat and modify materials in a periodic way. Instead of using one tiny laser spot only, hundreds to thousands to millions “laser spots” are created simultaneously and used to treat the material. The applications are abundant.

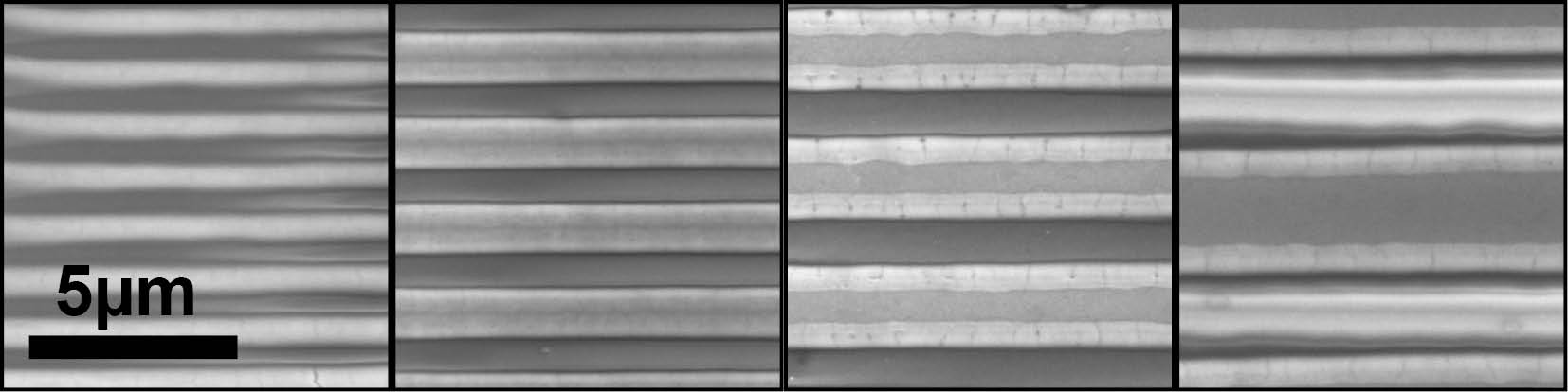

LALIP creates periodic surface structures by laser ablation. The result of LALIP are topographies that improve adhesion or electrical contact, channel microfluidics or improve lubrication, diffuse or refract light, change haptic properties, or simply enlarge the surface. A pure material modification by LALIP can yield metamaterials in which material properties depend on direction whereas a LALIP cutting process can yield thousands of perfectly parallel cuts with one movement.

Numerous application areas for LALIP

Possible LALIP applications areas are numerous can be found in for instance the aviation industry, wind power stations, pipelines, transportation vehicles and so on, wherever and whenever tiny, homogeneous and repeating patterns need to be created on large surface areas in an economical way.

LEAF — Drag Reduction for CO2 reduction and lower fuel burn

The LALIP principle is also core to our LEAF technology - short for Laser Enhanced Air Flow. Here we use the principle of laser interference to structure so-called riblets in paint systems for aircraft.

Contact us to stay informed about the progress of this development!

Technical Papers

A model for direct laser interference patterning of ZnO:Al – predicting possible sample topographies to optimize light trapping in thin-film silicon solar cells

Journal

Applied Physics A

122:445

DOI

10.1007/s00339-016-9974-1

Contact

We look forward to your questions – our experts are at your disposal.