Laser Patterning

PRECISION AND CREATIVITY FOR APPEALING PV MODULES

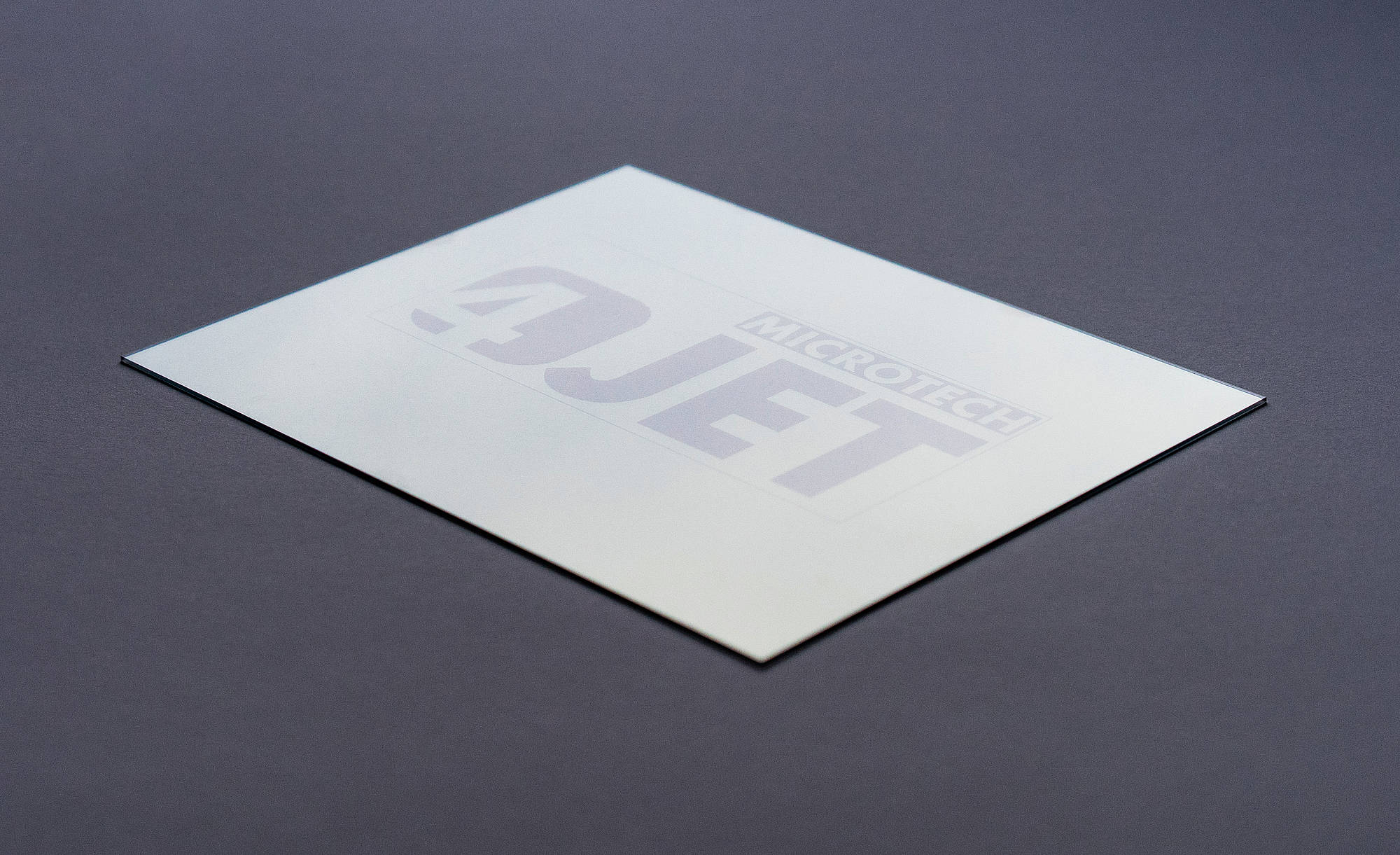

State-of-the-art laser structuring technology opens completely new possibilities for the production of semi-transparent and aesthetically pleasing PV modules. Thanks to the highest precision, there is no need to worry about disruptive interference. Even with complex contours, free-form processing enables extended design freedom.

The innovative technology also allows logos and even images to be easily created not only within a module, but also on much larger surfaces by cleverly combining individual modules with each other.

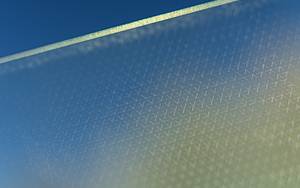

The basic idea behind laser structuring is to selectively remove or structure thin functional layers on glass while ensuring the highest precision and quality. These functional layers can include transparent conductive oxides (TCO), metallic layers or photovoltaic absorber layers.

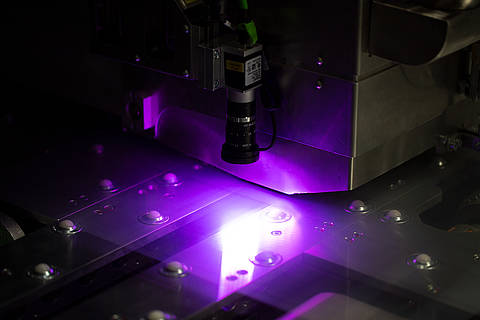

The right laser source is selected extremely carefully, taking into account pulse length, pulse energy and beam shaping to achieve the best possible results. Our expertise in laser source selection and matching is the key to outstanding processing efficiency and quality.

We rely on years of experience and a modern laboratory to analyze and continuously optimize the quality of material processing. With our support, you can achieve perfection in your PV modules and create innovative solutions that are both aesthetically pleasing and functional.

Laser structuring technology enables the development of PV modules that not only generate energy efficiently, but also take the design of your application to a new level. From architecture to solar technology, rely on precision and creativity with our laser structuring technology.

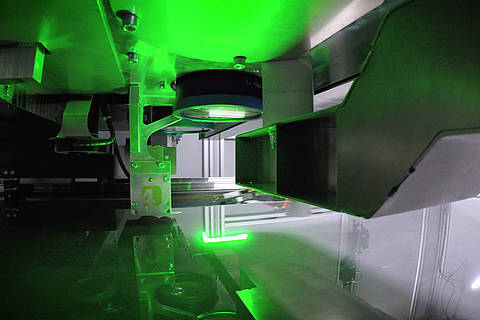

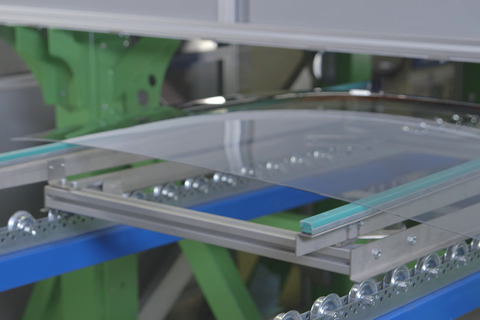

4JET's solution for the perfect function on transportation glass

Meet our TOPAZ line – designed for flexible, high-accuracy and cost-effective laser glass patterning enabling the perfect function in transportation glass applications.

Contact

We look forward to your questions – our experts are at your disposal.